What Are Paint Agitators Used For

What are Agitators?

An agitator is a mechanical device that helps in shaking or stirring a liquid or mixture of liquids. Agitators are widely used for multiple operations in the chemic, pharmaceutical, nutrient, grease, metallic extraction, paint, adhesive, water, and cosmetic industries.

What are agitators used for?

The main functions of using an agitator in whatsoever plant are:

- To become proper mixing of liquids.

- To promote chemical reaction inside the equipment.

- To increase heat transfer during heating or cooling

- To proceed homogeneous liquid bulk during storage.

- To disperse immiscible liquids.

- To keep the product in a mixed state till used.

- To blend miscible liquids.

- To dissolve some solids into liquid.

The agitators are defined as a automobile where an impeller with a rotating shaft imparts energy by mechanical means to mix various process media.

What are the Types of Agitators?

Various types of agitators are bachelor for industrial purposes. The mutual type of agitators are:

- Paddle Agitators

- Anchor type agitators

- Propeller type agitators

- Bract type agitators

- Turbine type agitators

- Helical Agitators

i. Paddle Agitators: Containing paddle-shaped blades, these agitators are the about bones types of agitators. Their adequacy is limited and used mainly for laminar flow fluids requiring niggling shearing. They are adjustable and incorporate an equal number of forwarding and reversing paddles to motility ingredients from one end of the vessel to the other.

A modified version of paddle agitators is Sawtooth Paddle Agitators. The frontwards puddles of such agitators contain notches or saw teeth.

2. Ballast Agitators: For mixing highly viscous and not-Newtonian fluids, anchor agitators are widely used. Their name indicates the impeller shape that resembles an ballast. They are normally mounted in tanks and vessels with conical or rounded bottoms.

three. Propeller Agitators: For low viscosity products, Propeller agitators are highly suitable. Functions similar homogenization, suspension, dispersion are easily achieved using propeller-blazon agitators operating at medium to high speeds. These axial flow agitators are ideal for solid in liquid suspensions equally they forestall the deposition of solid particles.

4. Blade Type Agitators: These are suitable for low and medium-viscosity fluids. Blade type agitators are axial blazon.

5. Turbine Agitators: For emulsification and dispersion of fluids at very high speed, Turbine agitators are used widely. Turbine Agitators are characterized by highly constructive mixing adequacy across a broad viscosity range. Turbine agitators have an axial input and radial output. They combine rotation and centrifugal motility during working.

6. Helical Agitators: As the blades are arranged in a structure of a helix, they are known as helical agitators. Appearing similar a threaded screw, helical agitators are axial flow agitators that provide vigorous movement within the vessel or tank. This type of agitator is widely used in polymer industries.

The following table provides the main applications, advantages, and disadvantages of various types of agitators.

| Type of Agitator | Applications | Advantages | Disadvantages |

| Paddle Agitator | Mixing of Solids, Slurry Mixing, Used during Crystals forming phase during Supersaturated Cooling | Heavy-duty, Slow Operation, two to 4 blades. | Loftier power consumption, Inefficient mixing. |

| Turbine Agitator | Liquids and gas reactions, widely used for reaction and extraction operations. | Loftier radial flow, good for dispersion operation. | Not preferred for highly viscid solvents |

| Anchor Agitators | Widely used in the pharma manufacture. | Loftier heat transfer charge per unit. | High power and high-efficiency gearbox requirement. |

| Propeller Agitators | Can handle corrosive materials with a glass lining. | Increase homogeneity. Can be used for drying and pressing. | High-speed requirement. |

| Helical Blade | The Pigment Industry. | Tin efficiently handle visco-elastic liquids. | Low possibility for radial Mixing. |

Components of an Agitator

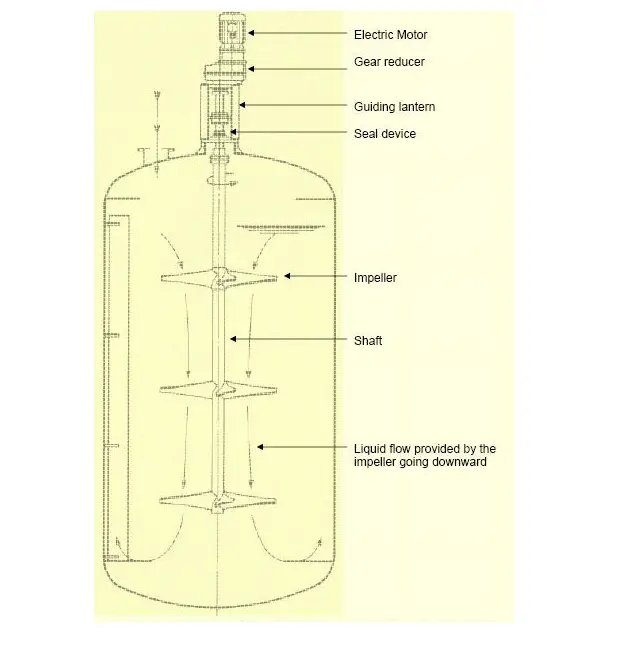

An agitator is ordinarily equanimous of iii principal components. they are:

- A shaft with an impeller and impeller blades

- A mechanical seal and

- A motor with a gearbox option for speed control.

The shaft of the agitator is connected to the motor and gearbox and the impeller rotates to perform mixing. The number of impellers depends on the height of the liquid inside the vessel or tank. Each impeller usually has two to 6 blades. Magnetic-driven agitators are as well bachelor where a hermetic seal is used in place of a mechanical seal. Fig. 2 below shows typical components of an agitator (Reference: Wikipedia)

The impellers used in agitators can be of various types like:

- Standard or Wide blade Hydrofoils

- Straight bract or Pitched blade turbines.

- Retreat curved impellers.

- Gas dispersion impellers.

- Rushton turbine impellers

- Sawtooth disk impellers, etc

Selection Criteria of Industrial Agitators

The choice of agitators for a particular application depends on various factors like:

- The phase to be mixed (unmarried-phase or multiphase).

- The viscosity of the bulk.

- Exact function required (blending, dissolving, dispersion, estrus commutation, chemic reaction, crystallization, emulsification, suspension, etc).

- The mixing cycle (batch size, the time required for agitation, material addition sequence, etc)

- Properties of the materials to exist mixed.

- Initial ingredient and last product viscosities.

- Solubility of solids and concentration used.

- Desired process outcomes.

- Corrosive or flammable properties.

Number of Agitators

In that location could be more than i agitator connected to the shaft. The number of agitators and Gap betwixt two agitators tin can be institute from the following equation:

Number of Agitators=(Maximum liquid elevation 10 Specific gravity)/Diameter of the Vessel.

The gap between ii Agitators=Liquid Elevation/(Number of Impellers-0.5).

Data required for the design of an Agitator

The post-obit data are required for the industrial blueprint of an anarchist:

- Purpose/Function of agitation.

- Mixing cycle.

- Foaming tendency

- Private physical characters and their quantities of the materials to exist mixed.

- Tank/Vessel/Reactor dimensions preferably with a sketch.

- Duty hours.

- Electrical duties

- Material of Construction

Applications of Industrial Agitators

Industrial agitators are used in various applications like

- Mixing in tank

- Sticky products and non-newtonian liquids

- Clean and lightly contaminated liquids,

- Fibrous and Non-gristly slurries

- Liquids with high gas or solid content

Source: https://whatispiping.com/agitators/

Posted by: richmondsperwit.blogspot.com

0 Response to "What Are Paint Agitators Used For"

Post a Comment